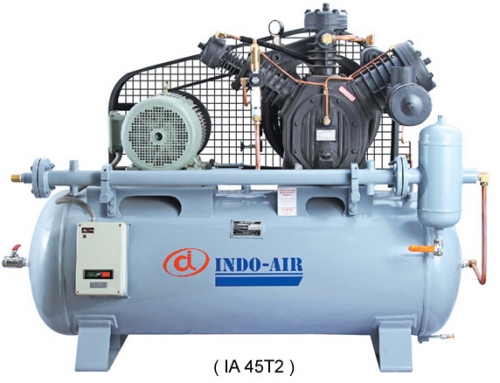

Project Description

Single stage reciprocating air compressors are perfect for light work at home and/or in small workshops.Single-stage air compressors are designed for Low Pressure Application These Compressors have Cylinders of same size (regardless of the number of cylinders). Robust overhung design crankshaft for reliability &easy maintenance, solid end connecting rods, highly thermal efficient intercooling, totally reliable splash lubrication & balanced V-type construction for smooth vibration free operation. A single-stage air compressor works by drawing air into the compressor’s cylinder, where it is then compressed with a single stroke of a piston and sent to a storage tank. This differs from a two-stage air compressor where, after the initial compression, the air is delivered to another high-pressure piston via a specially designed intercooler tube for a second compression. Depending on the model, a single stage air compressor can provide a pressure between 110 and 135 psi, while two-stage compressors can deliver up to 175 psi.